HOME > Honing Technology

Honing Technology

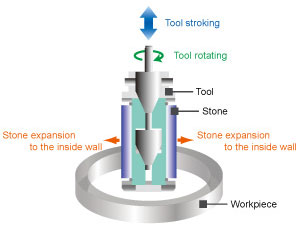

Honing is a kind of grinding processes to grind workpieces by abrasive stones. Honing process is pushing multi-stones set in the honing head against the workpiece surface and grinding by combination of rotation and stroking the tool.

Honing ProcessHoning Theory Diagram

- Improve roundness or cylindricity of the pre-processed cylinder.

- Desired roughness of the surface is attained by using different grit size stones properly.

- High-efficiency grinding is realized through sheet-like honing by using multi-stones.

- Honing along the pre-processed bores does not need accurate workpiece positioning against honing axis.

- Difficult long bore inside honing is practicable.

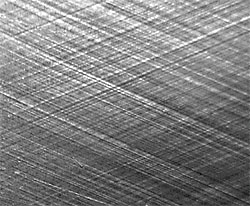

- The proper crosshatch that works as a groove for fixing oil on the cylinder surface can be formed by desired angle and depth.

Crosshatch example

Automobile & motorcycle

| Pinion gear | Rocker arm | Turbocharger parts |

| Spur gear | Helical gear | Crankshaft pulley |

| Steering parts | Hydraulic valve | Small engine |

| Mission gear | Two-wheel engine | Engine block |

| Power steering tube | ||

Marine vessel

Liner & sleeve for large-size vessel

Airplane

| Landing gear | Various kinds of bearings |

Railway

Wheels & bearings

Industrial instrument

| Multiple manifold, etc. |

Electric appliance

| Freezer cylinder | Freezer slider | Freezer frame, etc. |

Hydraulic equipment

| Gear pump | Hydraulic valve body |